Advantages of digital transfer print

- Bespoke service

- No minimum quantities

- Print on demand

- High quality fabric

- Double sided printing possible

- Colourfast performance

- Economic and efficient

- We can respond quickly to demand

Transfer printing

Transfer printing has been around for around 50 plus years as a means of applying coloured prints to polyester fabrics. In 1995 it became an integral part of sharps business. Although a competitive market and relatively inexpensive printing technique by concentrating on higher quality furnishing fabrics a steady growth with a strengthening client base has been achieved.

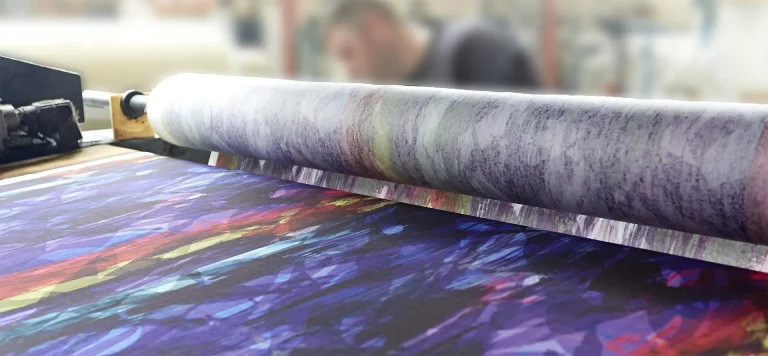

The simple method of transferring dispersed dyes printed on a paper carrier directly onto the fabric by heat and pressure revolutionised the design concept previously not achievable with traditional printing methods.

It combines the relative ease of printing onto paper. A quality paper can be printed and stored until an order is received for the fabric. This reduces waste and turnaround time. No further processing is required and the fabric is ready to use straight away.

Digital sublimation paper printing

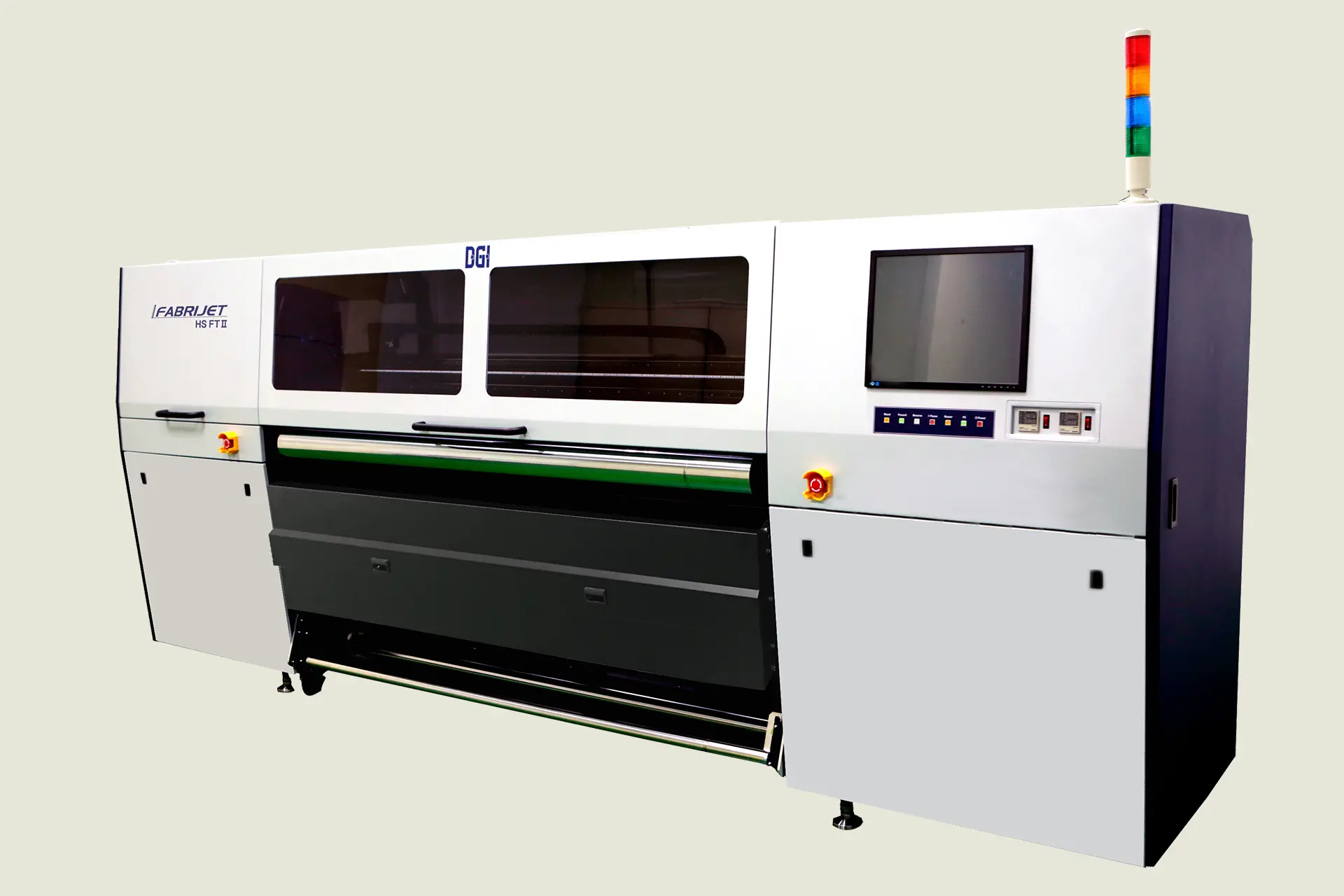

Sharps were the first UK company to introduce the high-speed industrial dye-sublimation print machine for mass production.

The Fabrijet is a print machine system based on the advanced, durable Kyocera print head.

It has excellent printing quality based on variable dot technology.

The high speed allows us to print up to 1000m of paper on each of the machines, improving lead times.

What is digital sublimation printing?

Select a design from our design library – or send us a design file of your own.